ICPSS Lecture Notes - Lesson 6 - Introduction To Industrial Control Systems & Operations

Intro To Industrial Control Systems & Operations

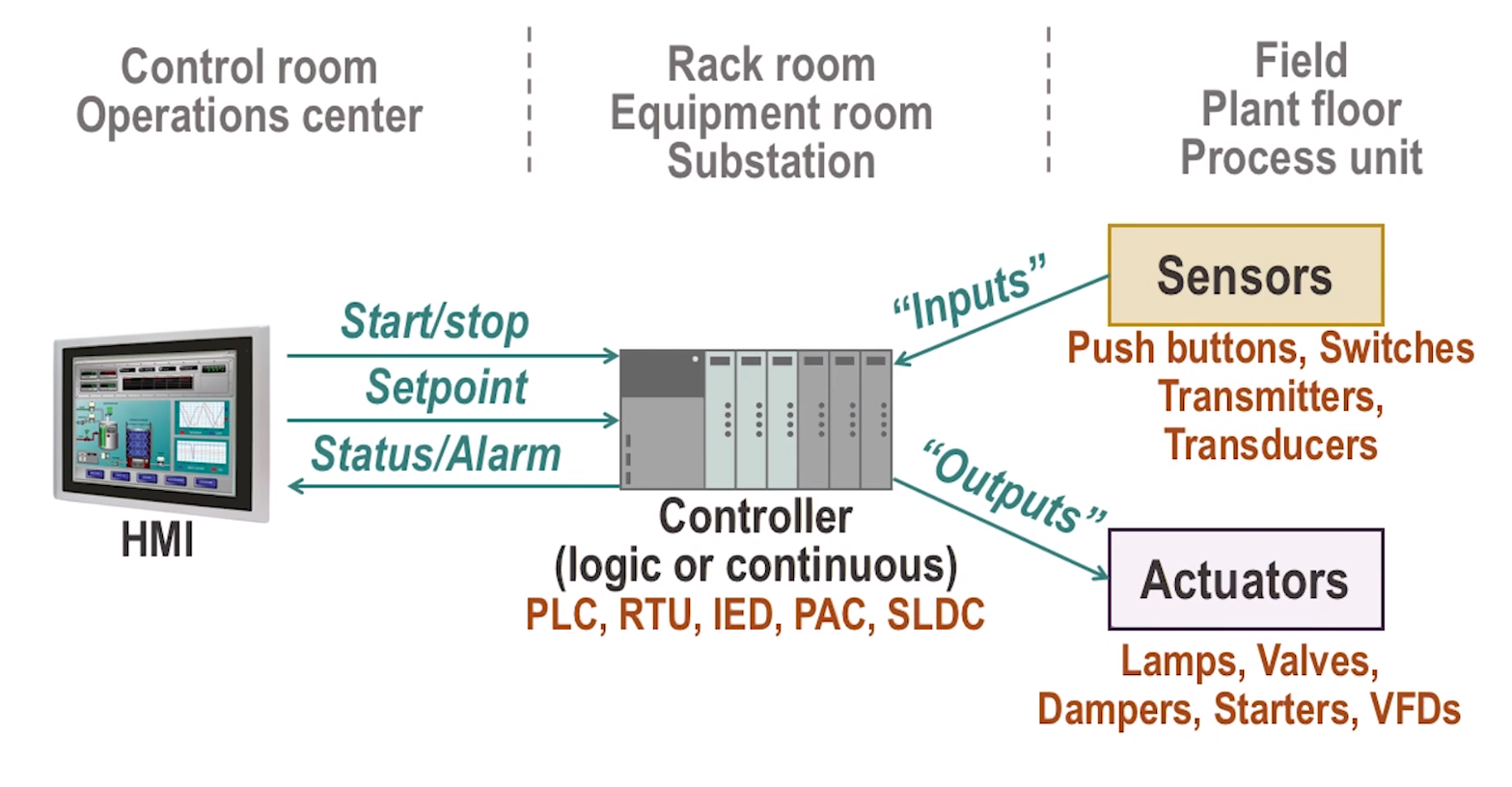

System Assets

- Sensors

- Actuators

- Gauges

- Motor Drives

- Indicators

- PLCs

- RTUs

- IEDs

- HMIs

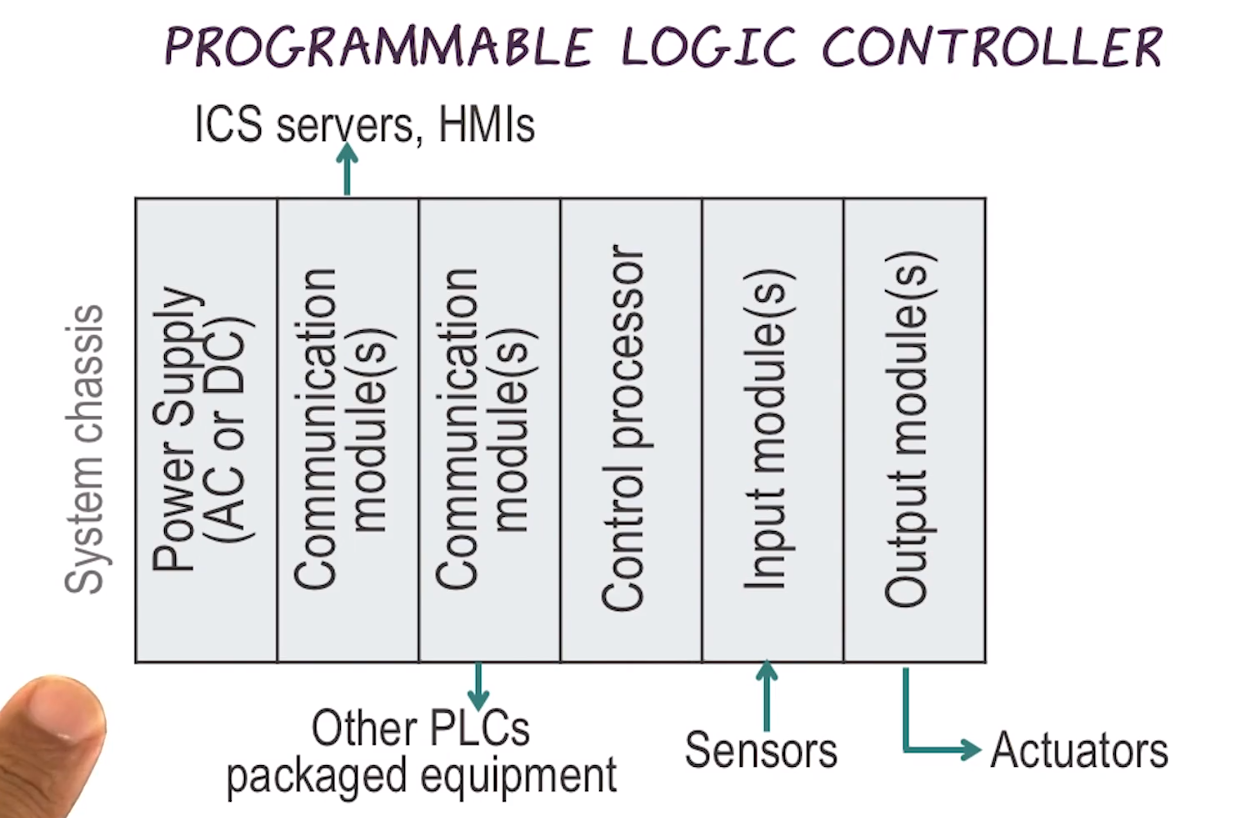

PLCs

- Programmable Logic Controller

- A specialized industrial computer used for automation

- Unlike desktop computers, PLCs are typically physically hardened and may be specialized for specific industrial uses with multiple specailized inputs and outputs

- They do not usually have an OS. They usually rely on specific application programs that allow the PLC to function automatically, generating output actions

- They typically control real-time processes

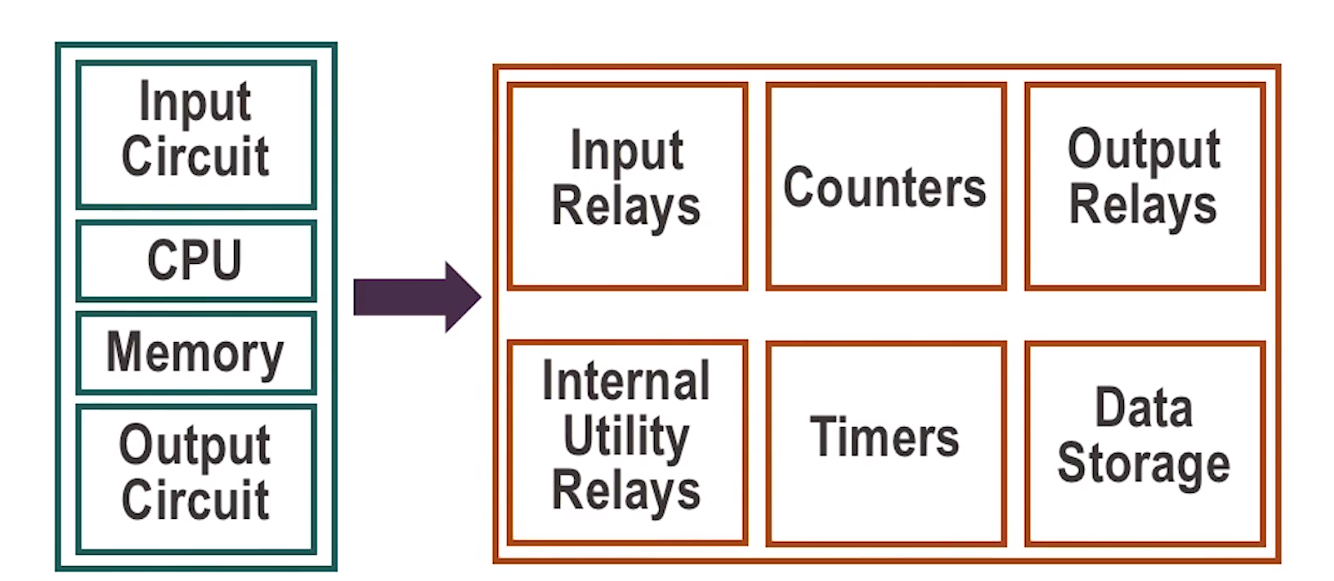

PLC Operation

- Works by continuously scanning a program in a loop

- Check input status

- Execute program

- may be conditioned on inputs

- Update output status

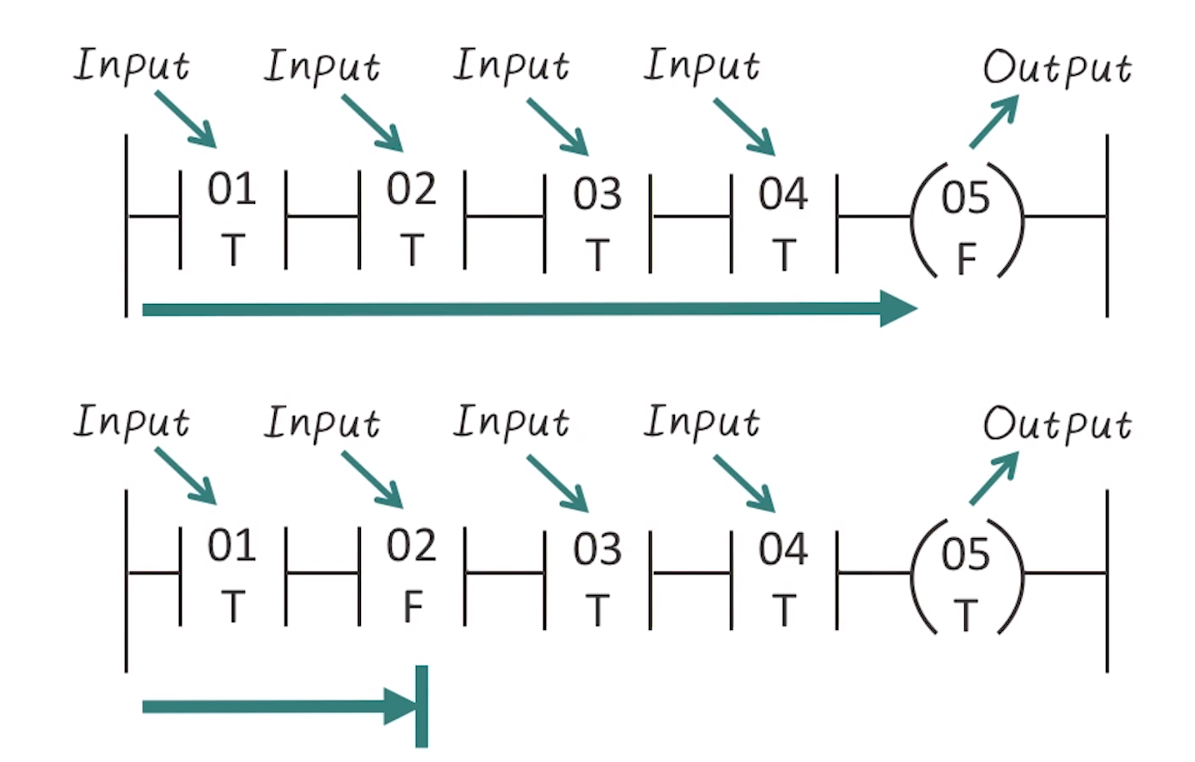

PLC Ladder Logic

- PLC’s can use ladder logic, which is a simplistic programming language built into them (included in the relevant standard)

- LL gets its name from the legacy method of implementing discrete logic from electromechanical relays

- Can be thought of a series of connections between relay inputs (inputs) and relay coils (outputs)

- If output is reached, coil is energized

- Switched can be used to compare a continuous digital input to a binary physical input (comparing to setpoints)

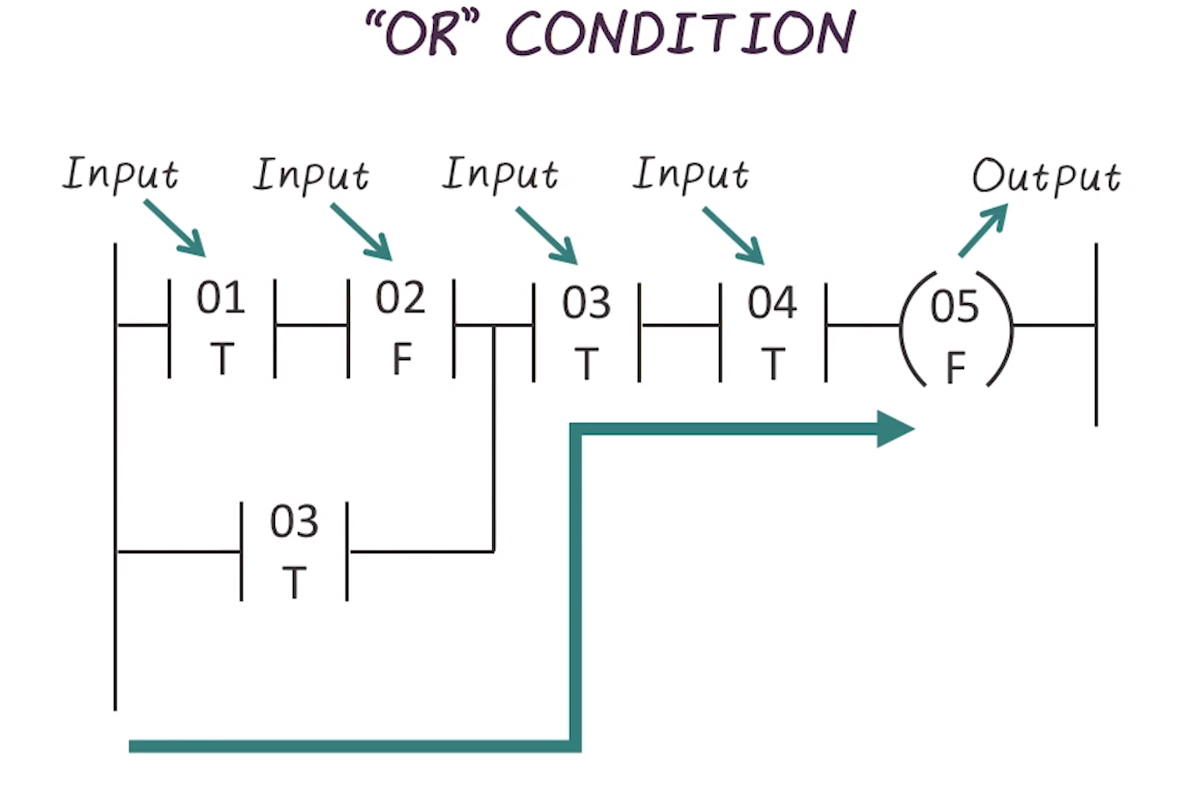

- logic can be more complex, see here an “or” condition

Other languages

- Standard includes ladder logic as mentioned above.

- Also includes:

- Structured Text (ST)

- Function Block Diagram (FBD)

- Instruction Lists (IL)

- Sequential Function Charts (SFC)

Remote Terminal Unit (RTU)

- Often reside in substation or otherwise remote location

- Monitor field parameters, and transmit back to monitoring station

- Usually include some way to beacon out, such as modem or radio

- Very limited bandwidth

- Thus, usually use minimalistic protocols such as “report by acception”

- Can be powered via solar or electric

- Often in extreme environmental conditions

- Modern RTUs overlap largely with PLCs, as tech advances

Intelligent Electronic Device (IED)

- Each industry has unique requirements, so equipment will vary from one to the next

- IEDs are used as bridge between analog and digital domains, used widely in power grids

- As with all tech, growing more sophisticated over time

- For this class, we can assume the IED supports a specific function within the overall control system, as opposed to RTU or PLC which are meant to be flexible enough for general use

Human-Machine Interface (HMI)

- Replace manual switches and dials with digital equivalents

- Much easier to adapt and adjust

- Can be run on either commodity hardware, or on industrial hardened machines with a touch panel

- Usually runs on Windows Embedded

- Allows “single pane of glass” control over complex processes

- Interesting note, usually no authentication to avoid password lockouts in emergencies

- Security is usually done at local workstation by restricting application execution, and also leans on physical security

Supervisory Workstations

- Read-only, strictly for monitoring use

- Can, however change parameters such as alarm limits or process setpoints

- HMI system or dashboard/workbook from data historian

Data Historian

- specialized software system that collects point values, alarm events, batch records, and other information from industrial devices or systems, and stores them in a purpose-built database

- There are some third-party vendors, but often these come from first party ICS vendors

- Data points referred to as ‘tags’ and can generally refer to anything

- Data often replicated across business and industrial networks

- This is a huge security concern, so historians must be hardened, and strict access controls put in place

Business Information Console

- Extensions of supervisory workstations

- Designed to deliver business intelligence to upper management

- Consist of same data obtained from HMI or data historian systems

- May be a physical console, or a historian with an ICS DMZ located elsewhere

Other Assets

- Printers

- Badge readers

- IP Telephones

- IP Cameras

- AD

- Time servers

- All of the above present attack surface and must be assessed

Control Loop

- Read data from sensors

- Execute logic against the data

- Write data to automation devices

- Go to 1

Closed vs Open Loops

- In closed loops, output of one iteration affects input of the next, while in open loop it does not

- Slides talk through example of ladder logic for cycling level in a water tank

- Slides talk through several examples around more complex control loops

Production Information Management

- All such processes and loops above must be managed from a central location, usually a data historian

- “Historizing” the data is the process of capturing and organizing the myriad data the control system generates

- From the historian, analytics are generated and used to inform the management of the system

- can be used to spot trend and anomalies, and optimize the process

Business Information Management

- Used to optimize for business KPIs

- Operational data in business network

- This reduces the strength of the security perimiter

- Each data access mechanism has security challenges

- Appropriate security mechanisms must be put in place

Process Management

- Driven by HMI

- HMI can be used to monitor output and adjust inputs or process setpoints

- HMI translates system functions to human-readable controls

- e.g. write single coil -> turn on water pump

- This means that compromising an HMI is a huge risk, as they functionally run the system

- e.g. Stuxnet

- However, attacker must have specific knowledge of the process in question to know which changes would actually have an impact

- This makes casual attacks harder, but is not a defense against targeted attacks

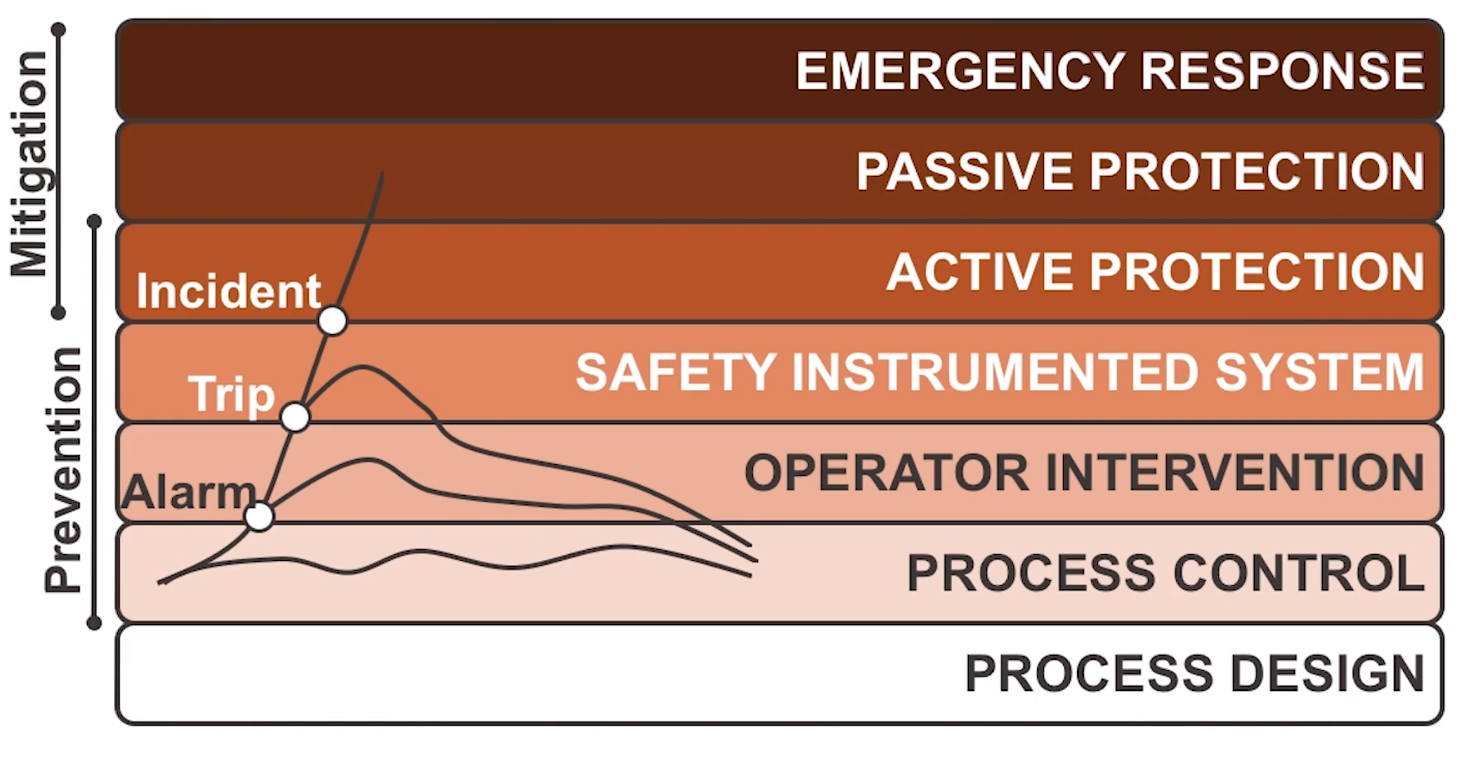

Safety-Instrumented Systems (SIS)

- Part of a layered stack of protections

- Helps as an automated safeguard before things become “incidents”

- If compromised, this safety is removed.

- Key part of a DoS attack

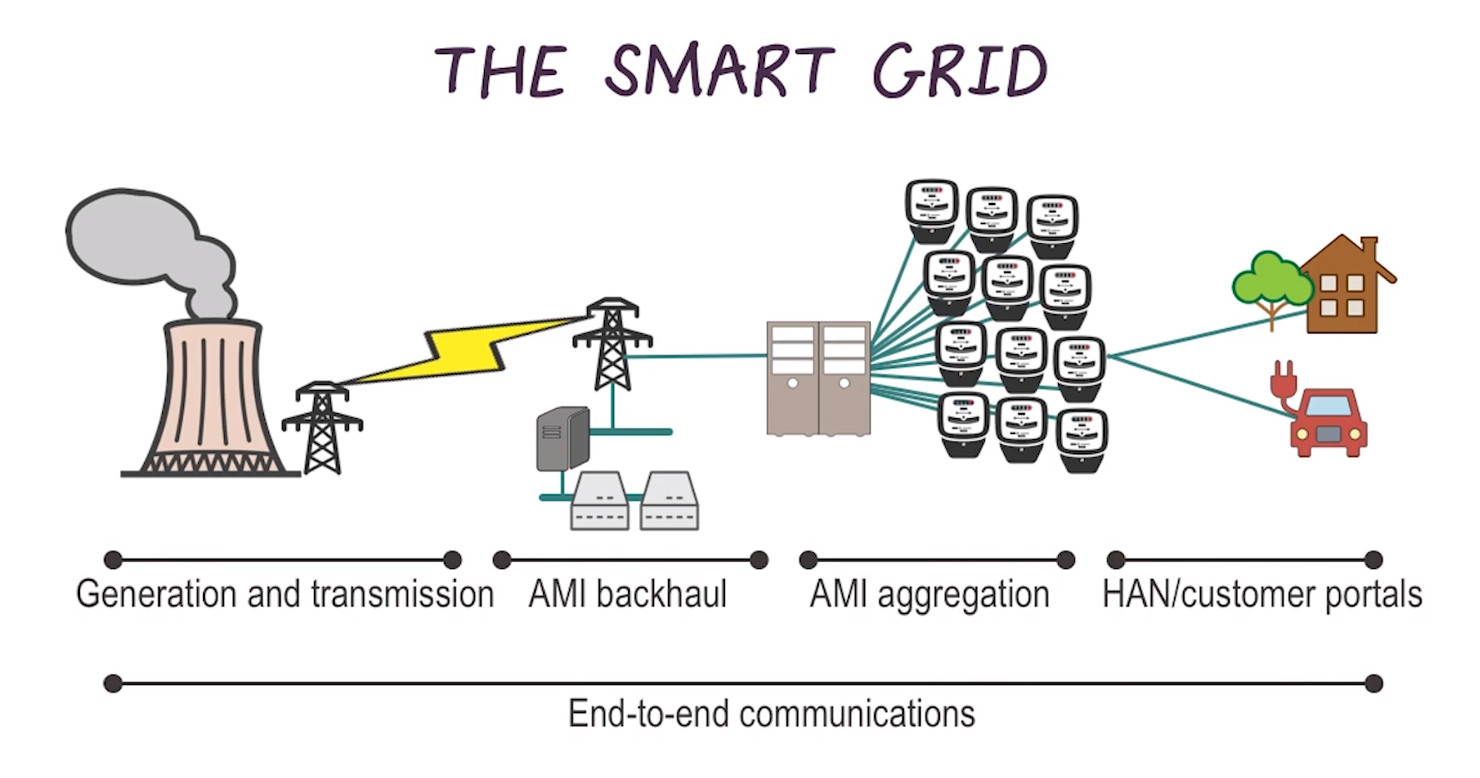

The Smart Grid

- An amalgamation of many industrial networks

- Built using the assets, processes, and controls discussed so far

- Because it’s such an amalgamation, attack surface is huge