ICPSS Lecture Notes - Lesson 9 - Industrial Network Protocols

Industrial Network Protocols

- Highly specialized protocols, designed for efficiency and reliability

- Common requirements include:

- Real-time synchronization

- Deterministic communication

- Many of these protocols forego security in order to meet ICS requirements

- Protocols deployed across Industrial networks

- Including WAN, business networks, plant and SCADA networks, and fieldbus networks

- Many of these protocols were only over serial channels, but have now evolved to work over ethernet using routable protocols

- For the most part, we can divide industrial protocols into two common categories

- Fieldbus

- Backend

- We’ll also discuss another which doesn’t fit into either bucket

Fieldbus vs Backend Protocols

- Commonly found in process and control

- Deployed to connect sensors and actuators to PLCs, and PLCs to supervisory systems such as HMIs

- Backend protocols commonly deployed on or above supervisory networks, and are used to provide efficient system-to-system communication

- We’ll dive into 5 common prococols

- Fieldbus

- Modicon Communication Bus (Modbus)

- Distributed Network Protocol (DNP3)

- Backend

- Open Process Communications (OPC)

- Inter-Control Center Protocol (ICCP)

- Other

- IEC 61850

- Fieldbus

Modbus

- Invented in 1979 by Modicon to enable PLCs to communicate with real-time computers

- Very widely supported

- Communicates raw messages without authentication or excessive overhead (obviously bad practice by modern standards)

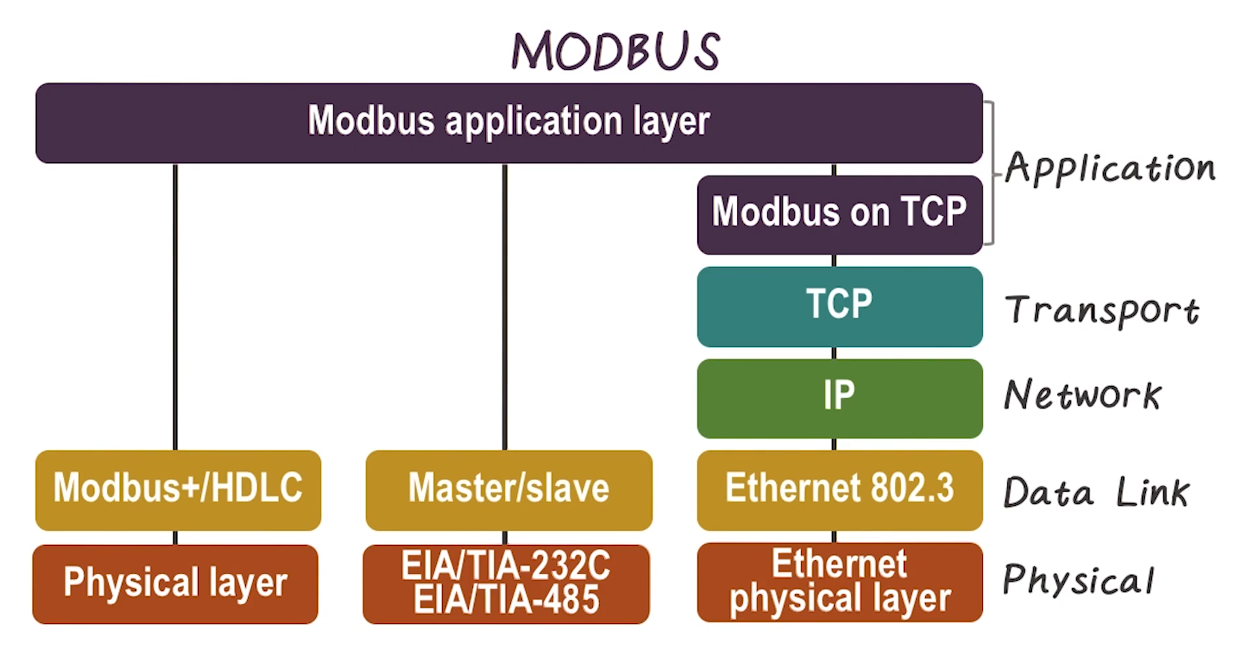

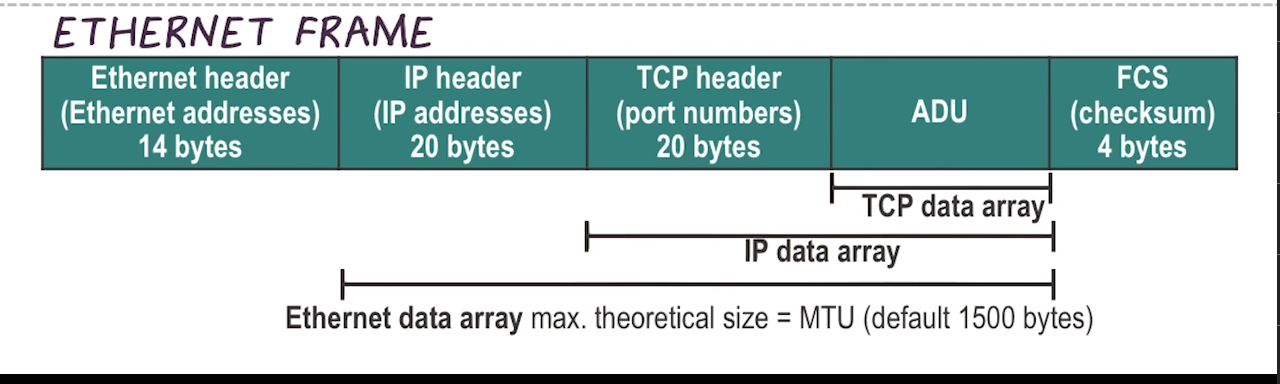

- Application layer protocol (Layer 5 in TCP/IP stack)

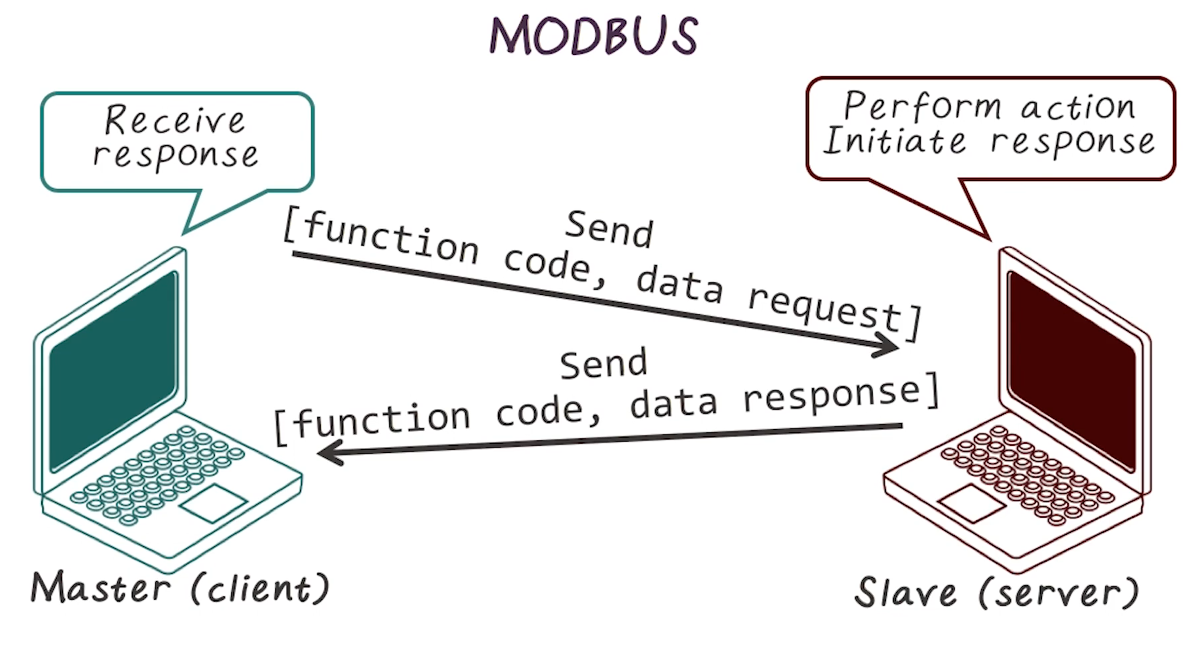

- Request-response protocol

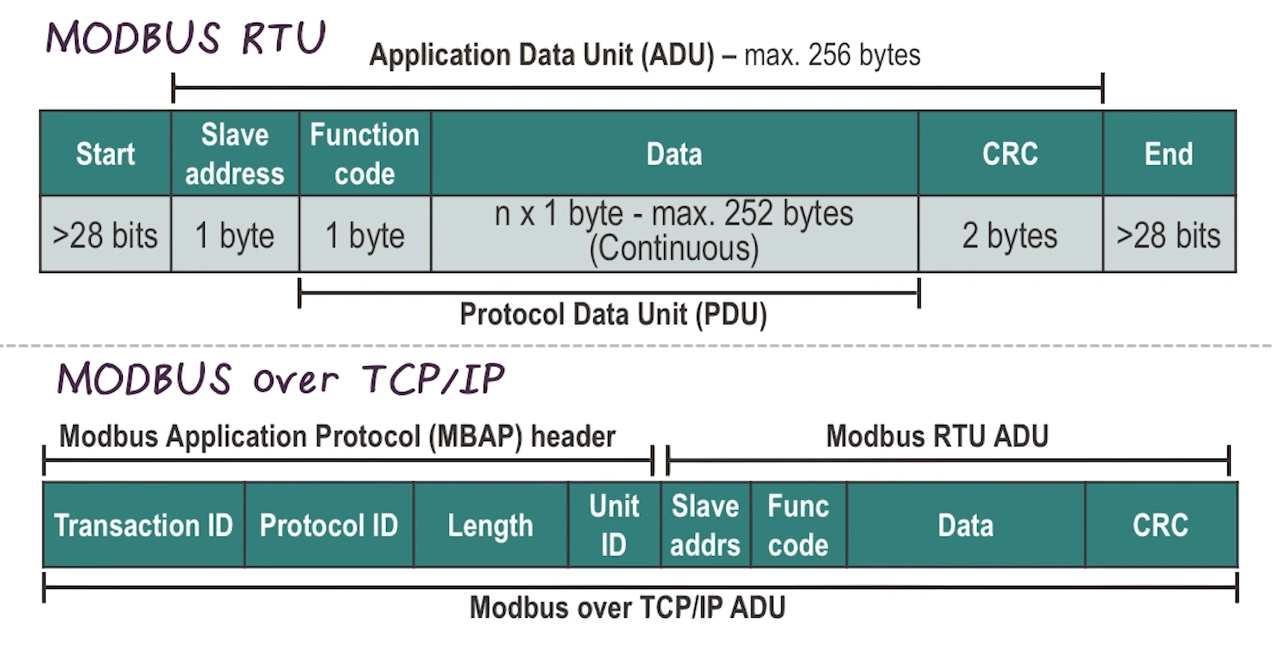

- 3 separate PDUs

- Modbus request

- Modbus response

- Modbus exception response

- 3 separate PDUs

- Commands are addressed to specific modbus address. While other devices may receive the message, only the addressed device will respond.

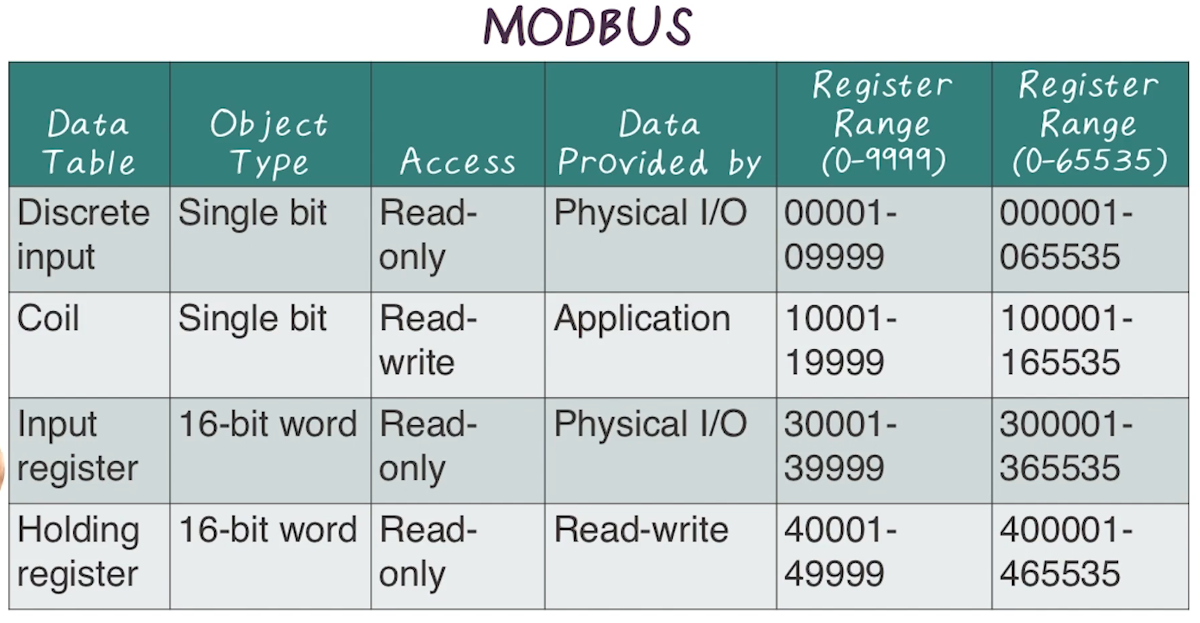

- Data housed in 4 tables, exact implementation is device-specific

Variants

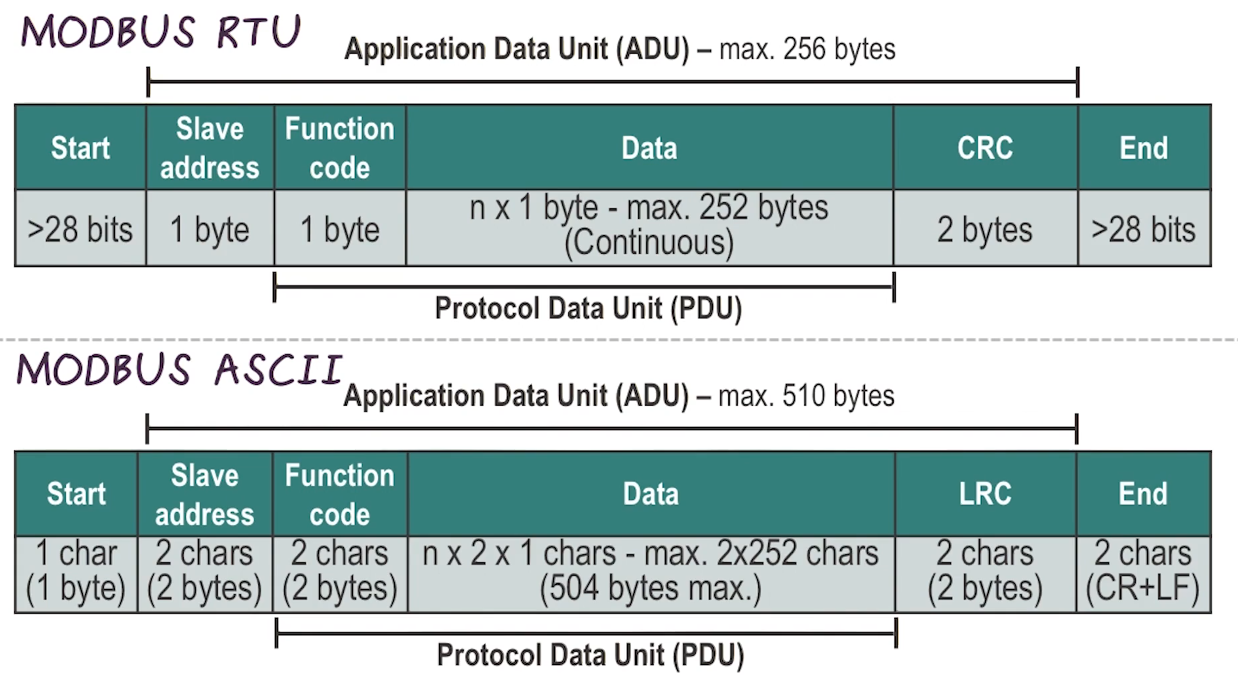

- Modbus RTU and Modbus ASCII

- Support binary and ascii transmissions over serial buses, respectively

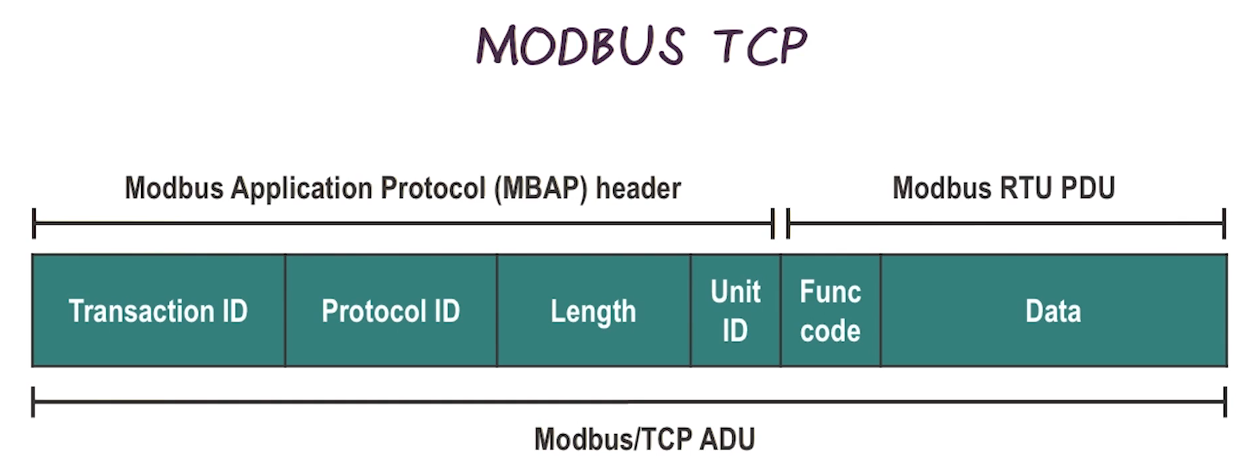

- Modbus TCP

- designed to operate on modern networks

- Modbus Plus

- designed to extend the reach of modbus for intereconnected buses using token-passing techniques

- Examples of PDUs for the variants. Many differences, as seen here

Security Concerns

- Lack of Authentication

- Only require use of a valid address, function code, and associated data

- Very simple MITM and Replay vulnerabilities here

- Lack of encryption

- Modbus addresses sent in the clear

- Lack of message checksum (Modbus/TCP only)

- Lack of broadcast suppression

- (serial Modbus only used in a multidrop topology)

Security Recommendations

- Only use between sets of known devices using expected function codes

- Monitor communication with ICS-aware intrusion detection system

- Whitelisting

- Application aware firewall for more critical areas to validate modbus sessions

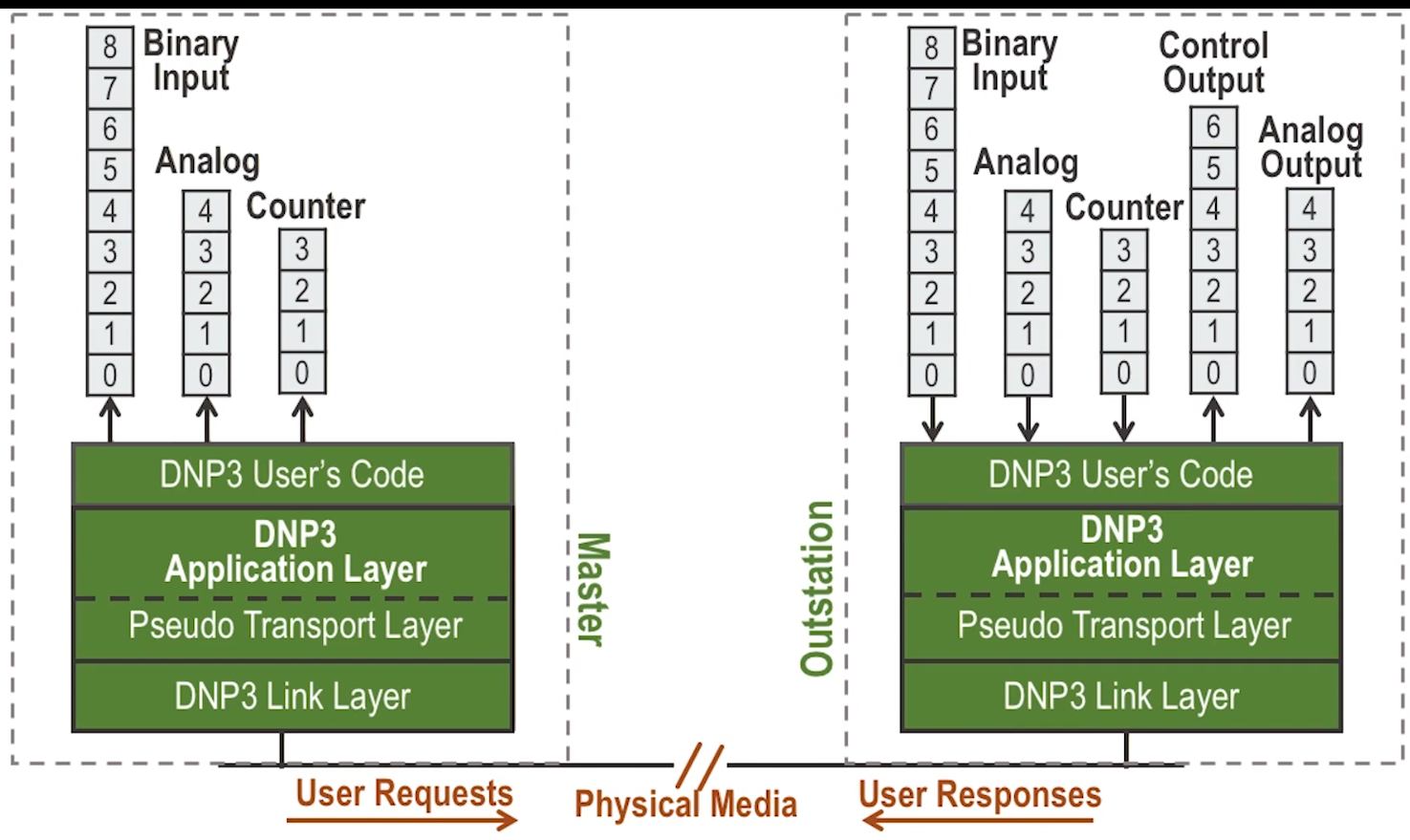

Distributed Network Protocol

- Began as a serial protocol much like modbus

- Designed for use between “master stations” or “control stations” and slave devices called “outstations”

- Commonly used to connect RTUs configured as “master stations” to IED “outstations” in electric substations

- Introduced in 1990 by Westronic

- Primary motivation for DNP3 was to provide reliable communications in environments common within the electirc utility industry that include high level of electromagnetic interference (EMI)

- Much higher degree of reliability than other industrial protocols

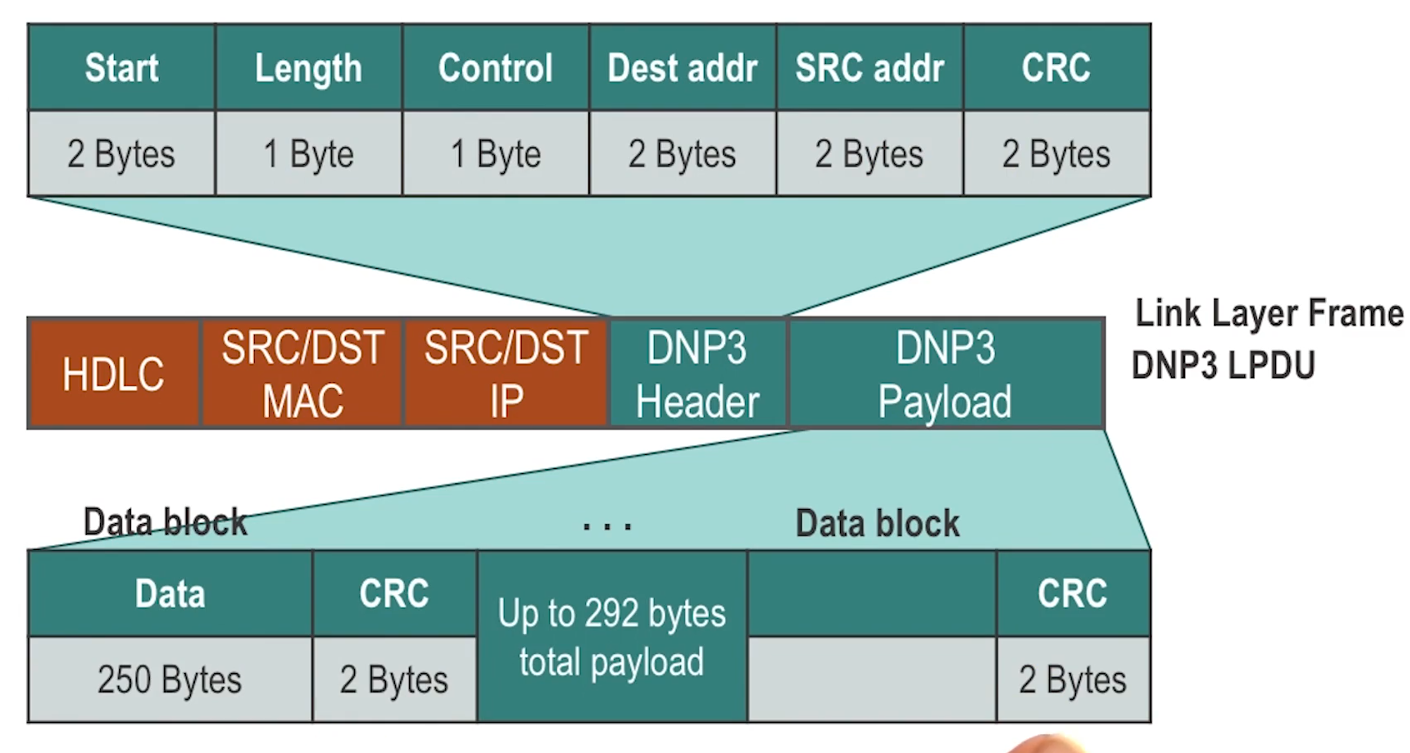

- Accomplished in part with many CRCs

- CRC is “Cyclic Redundancy Check” explained here

- DNP3 was extended to work over IP via encapsulation in TCP or UDP packets in 1998

- Now widely used in not only electirc utility, but also oil and gas, water, and wastewater industries

- Reasons for industry migration from Modbus are f[eatures used by other industries such as:

- report by exception

- data quality indicators

- timestamp data

- 2-pass “select before operate” procedure on outputs

- More reliable than Modbus while remaining efficient and well-suited for real-time uses

- Utilizes several standardized data formats and utilizes timestamps for synchronization of data

- Unlike Modbus and ICCP, DNP3 is bidirectional

- Therefore possible for a substation to initiate and inform the master station of events outside the norm

- Sits at application layer of TCP/IP stack.

- Has its own stack within the application, as shown in image above, corresponding to TCP stack, to offer features at each layer as appropriate

- Retransmission for CRC failure is ensured with multiple CRC embeddings withing header and payload

- DNP3 supports both static and event data, with classes thereof, for finer-grained and more efficient communication

- Provides a method to identify the remote device’s parameters to identify incoming messages and compare them to known point data

- This is efficient because it only requires the master to interact with relevant/changed data

- Request/response/ack communication pattern, as in other protocols. Multiple versions thereof

- Also supports unsolicited responses from outstations and “confirm ack” requests from master station

- Walkthrough of some pcaps of DNP3traffic

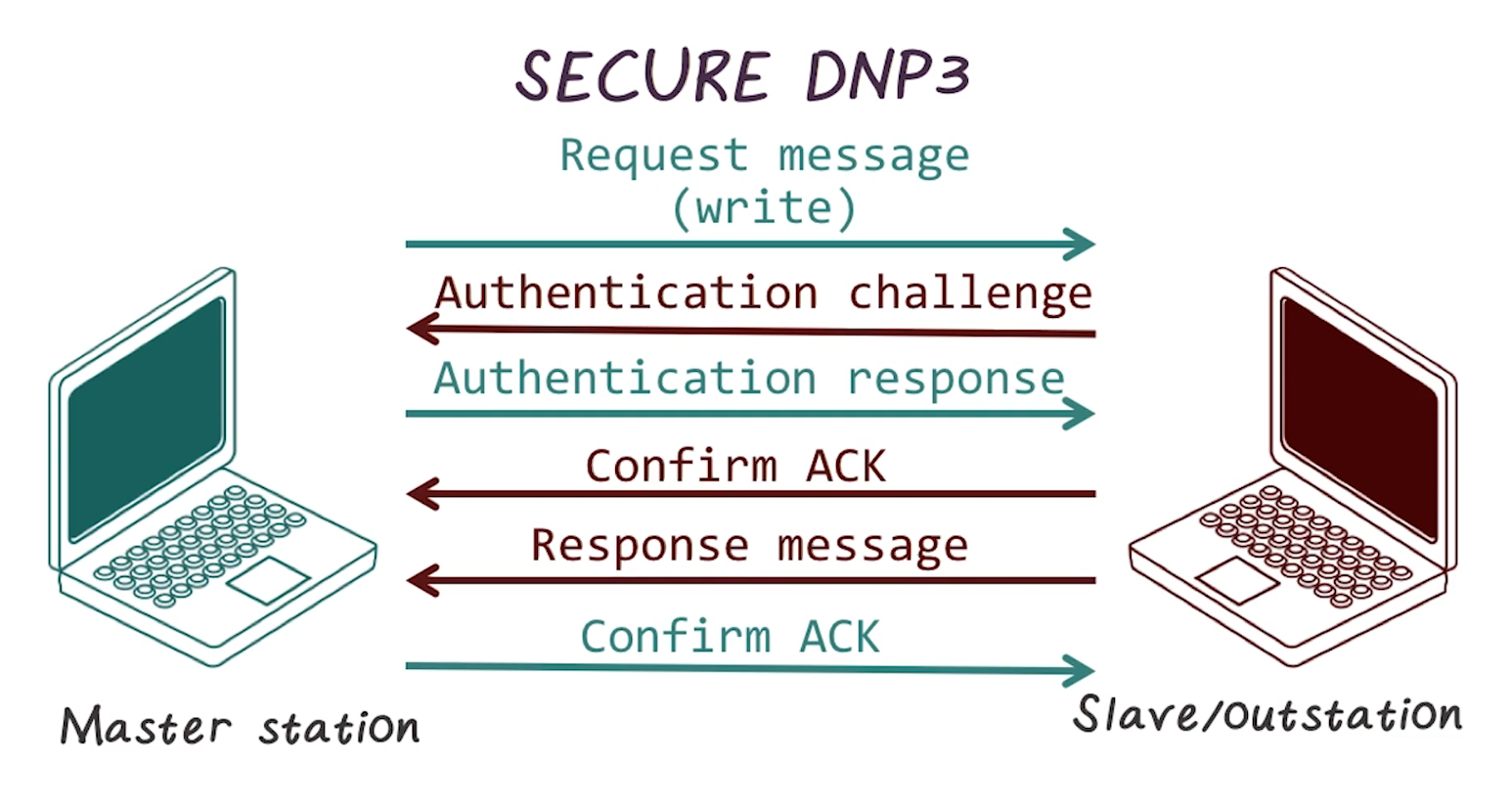

Secure DNP3

- Standard DNP3 does not provide any security. Secure DNP3 is a variant that adds authentication to the request/response process

- Challenge occurs on session initiation, potentially after a preset period of time, or on upon a critical request

- Uses a unique session key hashed together from information from both the sender and the challenger

- If using TCP, can also leverage TLS for encryption

- Thus, Secure DNP3 adds authentication, and if using TLS also adds confidentiality

- Often used between master control and an RTU, or between an RTU and different IEDs

Security Concerns of Regular DNP3

- Lack of authentication

- Lack of inherent encryption

- Fairly easy to manipulate due to well-defined nature of actions in the protocol

- Several vulns have been discovered and reported

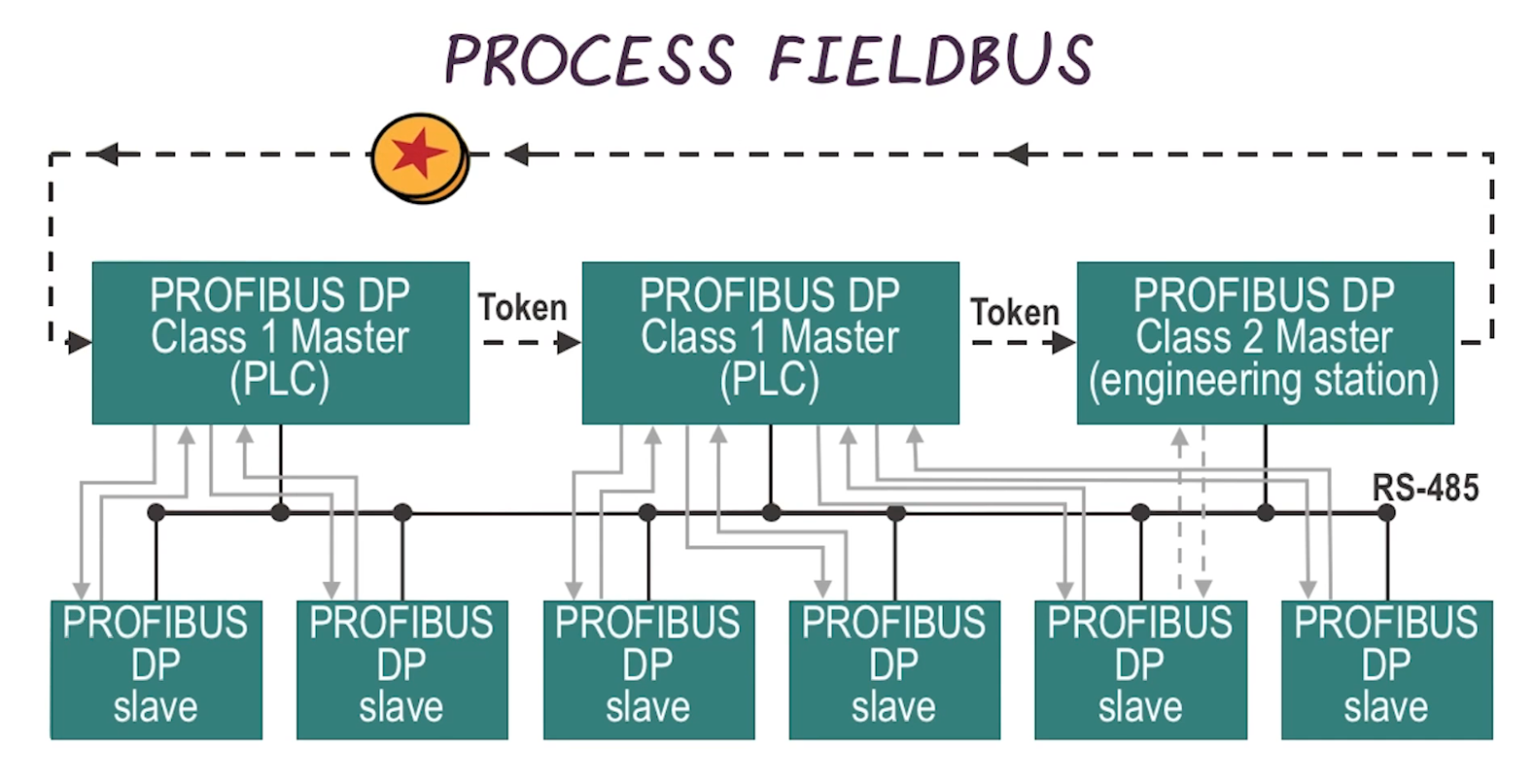

Process Fieldbus (PROFIBUS)

- Originally developed in the late 1980s

- Initially designed primarily to allow PLCs to communicate with host computers

- Several variants exist

- Profibus PA

- for instrumentation used for process automation

- Profisafe

- for safety applications

- Profidrive

- for high-speed drive applications

- Profibus DP (decentralized periphery)

- Most widely deployed. Itself has three variants

- DP-V0

- DP-V1

- DP-V2

- Each of these is a minor evolutionary step forward

- Three profiles for Profibus communication

- asynchronous

- synchronouse

- via Ethernet using ethertype 0x8892

- Profibus over Ethernet is also called PROFINET

- Profibus PA

- A master-slave protocol that supports multiple master nodes through the use of token sharing

- when a master has control of the token it can communicate with its slaves

- each slave is configured to respond to a single master

- slaves can initiate communication to master or to other slaves in the right conditions

- A master node is usually a PLC or RTU and a slave is usually a sensor or motor (or some other similar small component)

- Supports several physical layer deployments

- Abide by concept of intrinsic safety, meaning power levels too low to ignite fires

Security Concerns

- PROFIBUS lacks authentication inherent to many of its functions, allowing a spoofed node to impersonate a master node, which in turn provides control over all configured slaves

Security Recommendations

- PROFIBUS DP is a naturally segmented serial network

- Normally contained within a small geographical area, such as a section of a plant or manufacturing process

- Thus physical security is the main concern

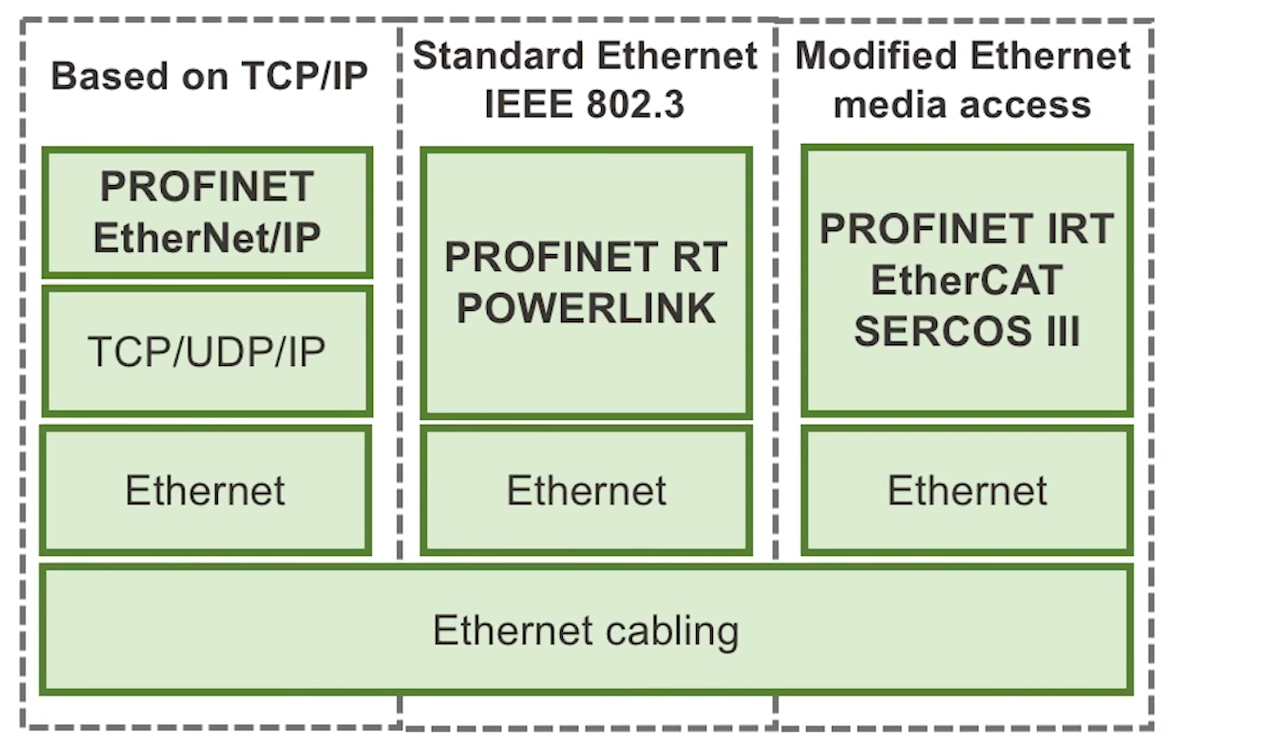

Industrial Ethernet Protocols

- Industrial Ethernet is the adaptation of the IEEE 802.3 Ethernet standard to real-time industrial automation applications

- General Ethernet does not provide QoS, so this is needed to allow real-time use

- One primary objective was to move toward more “synchronous” mechanisms of communication to prevent data collisions and minimize jitter inherent with “asynchronous” communications like standard Ethernet

- Allows technology to be deployed in critical, time-dependent applications

- Also provides physical enhancements to “harden” the office grade nature of standard Ethernet

- ruggedized wiring, connectors, and hardware

- There are 30 different varieties of Industrial Ethernet. We will discuss 5 (bolded above.

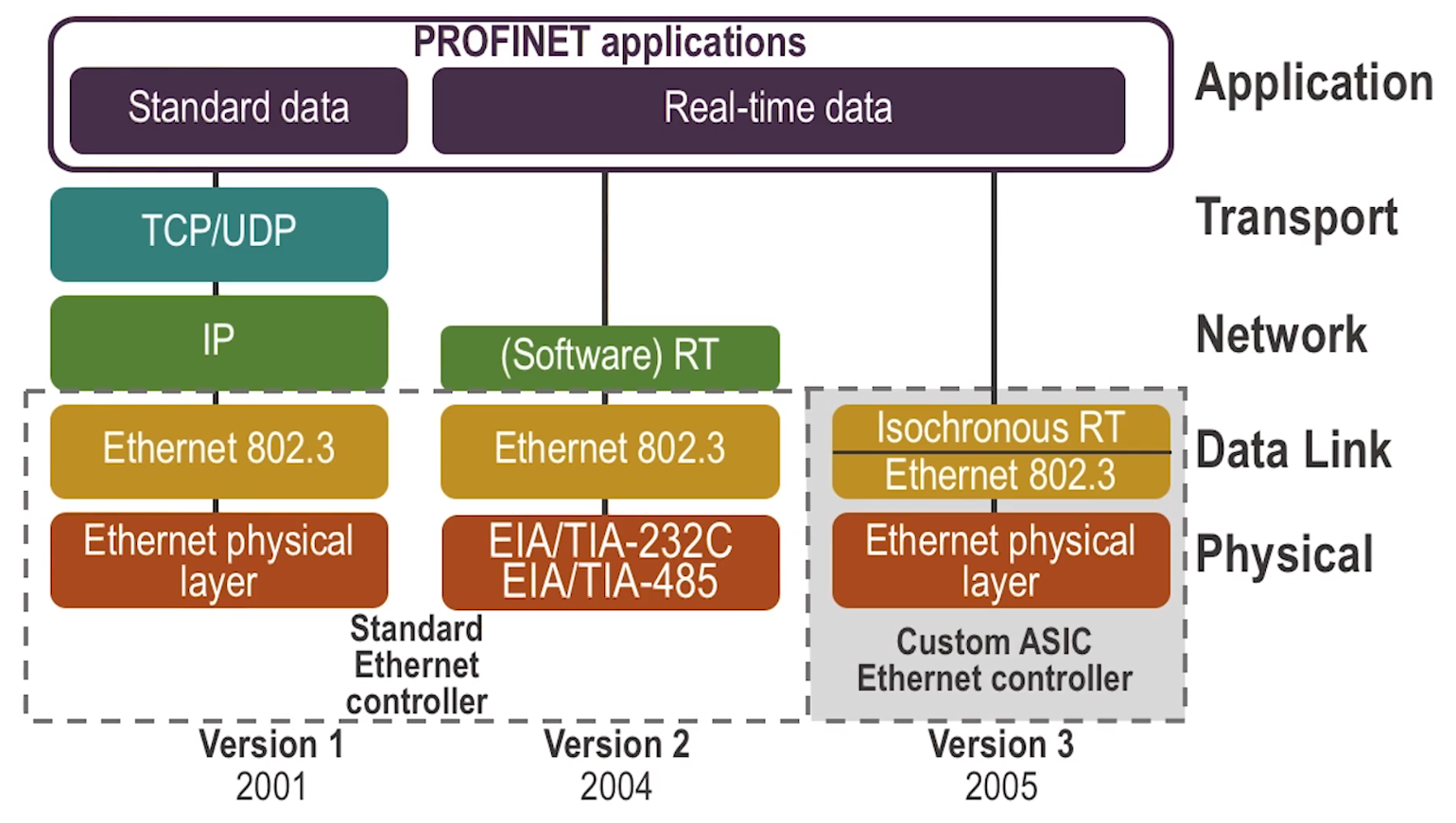

Profinet

- Designed for scalability. Can be deployed across varying network conditions. Each version improved reliability and cycle time speed.

- Security concerns

- Profinet is a real-time ethernet procotol, and as such is susceptible to any of the vulnerabilities of Ethernet

- Lack of authentication and inherent protocol vulnerability common to industrial protocols exacerbated by increased risk because this can be transmitted across standard enterprise and public networks (Ethernet is everywhere)

- Thus, Profinet TCP/IP should be tightly controlled. Within less-trusted business networks, used only over authenticated and encrypted networks

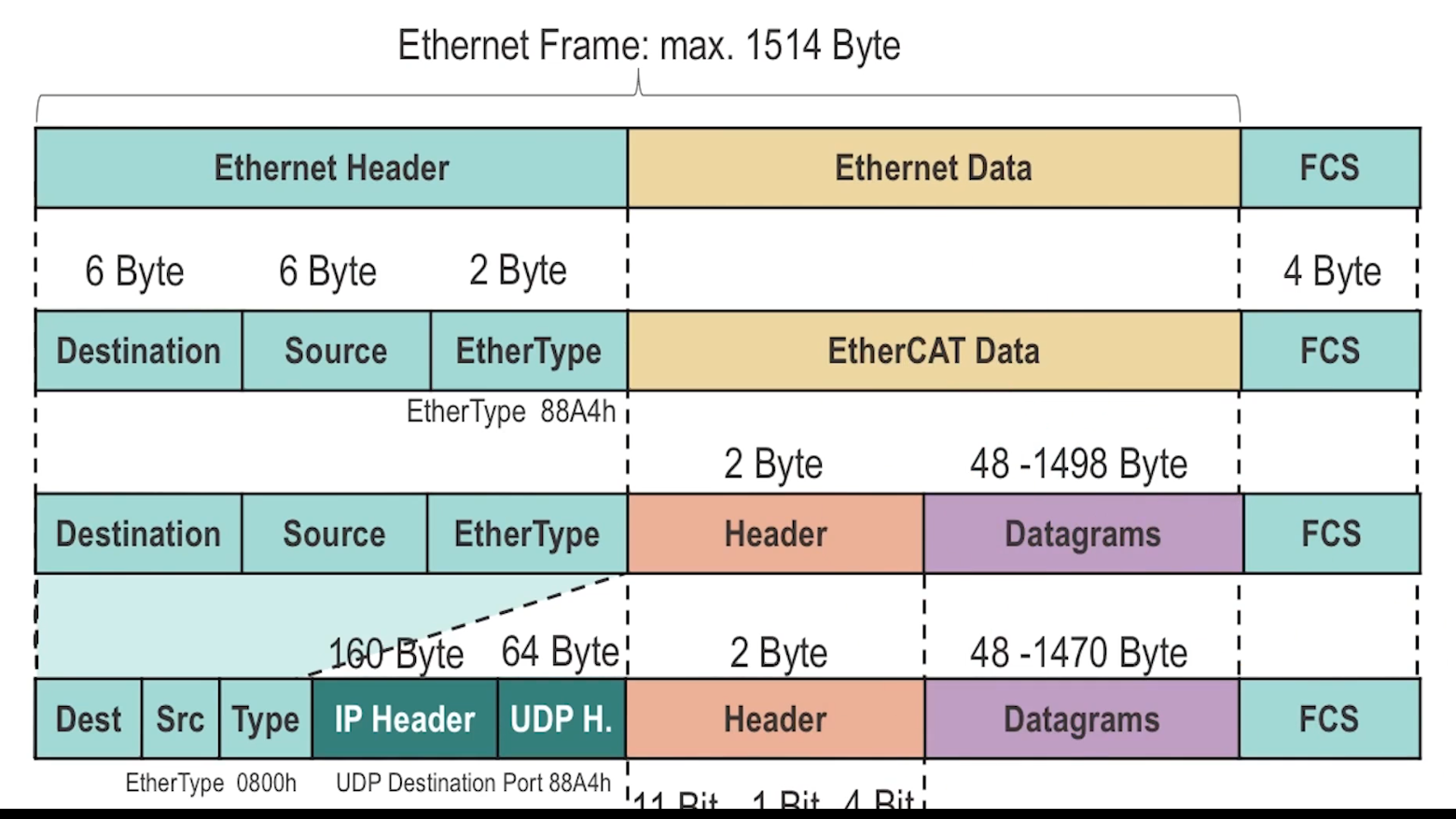

Ethercat

- Real-time Ethernet-based fieldbus protocol classified as “Industrial Ethernet”

- Messages can either be transmitted directly as an Ethernet frame, or encapsulated as a UDP payload

- Communicates large amounts of distributed process data with a single Ethernet frame

- This is good for efficiency because it means few cycles to communicate entire corpus of data

- Security concerns

- As expected, susceptible to all vulnerabilities of standard Ethernet

- EtherCAT is sensitive and highly susceptible to DOS attacks

- Security Recommendations

- secure perimiter

- passive network monitoring with whitelisting of devices

- ICS-aware firewalls and/or IDS

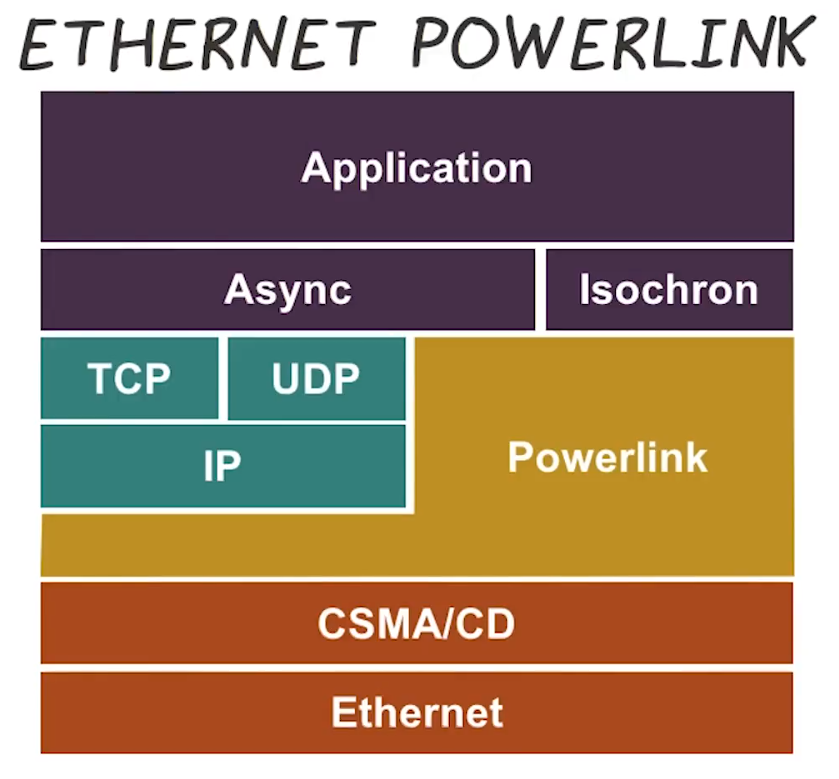

Ethernet Powerlink

- Directly encapsulates ethernet frames

- Cyclic polling of slave devices by a master node

- Multiple phases

- Start of Control

- Isochronous phase

- Slaves respond only if they receive a poll, preserving sequencing

- Asynchronous phase

- allows larger, non-time-critical data to be transmitted

- Process repeats

- Security concerns

- As expected, susceptible to all vulnerabilities of standard Ethernet

- Ethernet Powerlink is sensitive and highly susceptible to DOS attacks

- Easily disrupted via the insertion of rogue Ethernet frames into the network, requiring the separation of Powerlink from other Ethernet systems

- Security Recommendations

- Require a clear demarcation from other networks, needed by protocol anyway. Thus establish appropriate zones

- ICS-aware firewalls and/or IDS

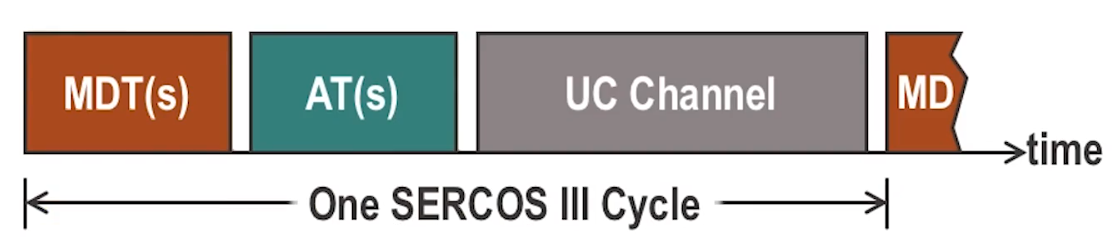

SERCOS III (Serial Real-Time Communication System)

- For communication between industrial controls, motion devices, and IO devices

- V1 and V2 were based on fiber optic ring, v3 is Ethernet-based

- Works directly on ethernet frames

- Supports many straight and rign topologies

- Master-slave protocol operating cyclically in which a single master synch telegram is used to communicate with slaves.

- Slaves are given a specific time in which they can place their information on the bus

- All messages for all nodes are packaged into a master data telegram (MDT)

- Each node knows which portion of the MDT it should read based on a pre-determined byte allocation

- Allocation Telegram (AT) is issued by master but populated by each slave with their appropriate response data.

- Multiple slaves share same AT

- Unified Communication (UC) phase the SERCOS network is open to allow ethernet frames or TCP/UDP traffic from other such devices

- Security concerns

- As expected, susceptible to all vulnerabilities of standard Ethernet

- SERCOS III is sensitive and highly susceptible to DOS attacks

- Through the UC Channel, also shares all vulnerabilities of enabled protocols, and can be used to attack other networks such as enterprise or industrial

- Security Recommendations

- Network isolation is critical

- SERCOS III should only be used on control loops that definitively require it

- IP Channels (UC Channel phase) should be restricted, or avoided if at all possible

- If used, the IP channels should be enclosed within zones consisting of SERCOS III master node and only required IP devices

- ICS-aware firewalls and/or IDS

Backend Protocols

Open Process Communication

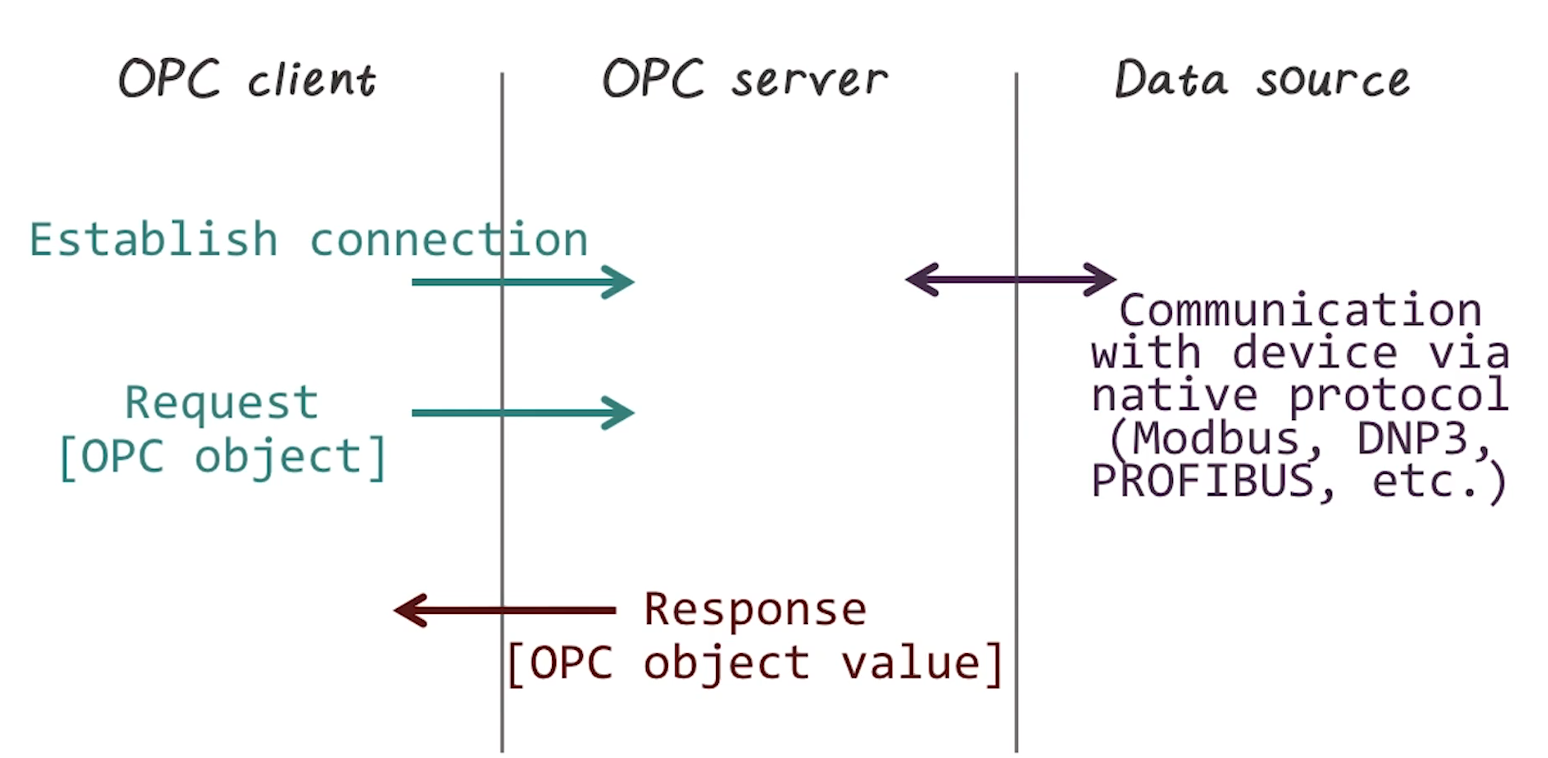

- OPC is not actually an industrial protocol, but instead a series of standards specifications

- Designed to provied a higher level of integration between systems and subsystems than a fieldbus protocol

- Motivated by needs of end users, as opposed to vendors, for interacting with different industrial devices

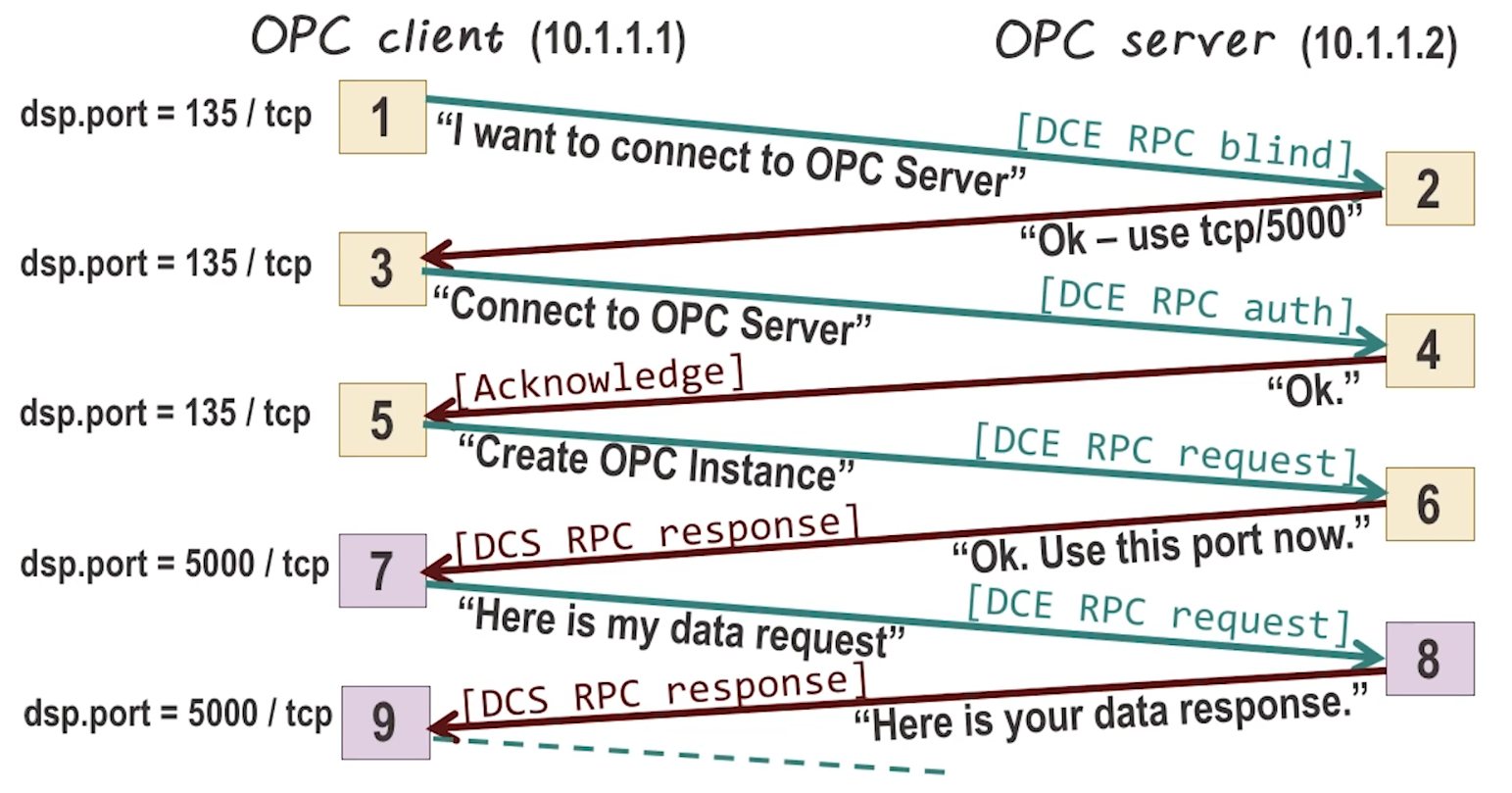

- OPC’s strengths and weaknesses come from its foundation

- Microsoft OLE is a big foundation

- Allows for data presentation to be separate from the application that generated it

- Client-server functional pattern.

- Client calls to server, process executes on server

- Uses RPC for calls

- Used in industrial networks, across many different use cases, to greatly simplify integration across devices

- Security Concerns

- OPC’s use of DCOM and RPC makes it highly vulnerable to attack using multiple vectors

- Shared attack surface with OLE, which is a very popular target

- OPC hosted on unsupported OS’s adds additional risk

- Many basic host security concerns apply because OPC is supported on Windows

- OPC host account on OS presents a big risk if overpriviliged, especially as it will be shared across hosts

- Basically, this is a modern tool on a (relatively) modern platform, so it’s a casualty of all the other threats targeting that platform

- OPC’s use of DCOM and RPC makes it highly vulnerable to attack using multiple vectors

- Security Recommendations

- The newer and designed for security Unified Architecture (OPC-UA) specifications should be used where possible

- Use best practices, as applied to any other windows box

Inter-control Center Communications Protocol (ICCP)

- Designed for communication between control centers within the electric utility industry

- Classified as a backend protocol because it was designed for bidirectional, WAN communication between control centers

- A standardized, common protocol was needed for communication between these disparate control centers which often do different functions and have different owners.

- Uses a master(client)-slave(server) model, with request/response pattern

- Primarily unidirectional, but modern implementations often allow hosts to function as both client and server creating a pseudo-bidirectional pattern

- Operates over almost any network protocol, but commonly uses ISO transport

- Effectively a point-to-point protocol due to use of bilateral table acting as an ACL for each control center

- Security Concerns

- ICCP lacks authentication and encryption and is therefore susceptible to any number of attacks (spoofing, session hijacking, etc)

- There is a Secure ICCP variant that incorporates digital certificate auth and crypt, but it is not widely used. It should be

- Explicitly defined trust relationships can be exploited

- e.g. if bilateral tables get compromised, the jig is entirely up

- Too accessible, as a WAN protocol. Lots of attack surface on WAN (e.g. WAN)

- ICCP lacks authentication and encryption and is therefore susceptible to any number of attacks (spoofing, session hijacking, etc)

- Security Recommendations

- Secure ICCP variants should be used wherever possible and supported by the current vendors installed within a particular site

- Patch and update, there are lots of known vulns for ICCP so leaving old versions up running across WAN is just asking for it.

- Extreme care should be taken in the definition of the bilateral table. It’s the firewall, any mistakes here are a big problem

- Standard modern best practices.

- ICS-aware firewalls and/or IDS

IEC 61850 Standard

- Doesn’t cleanly fit into either Fieldbus or Backend categories

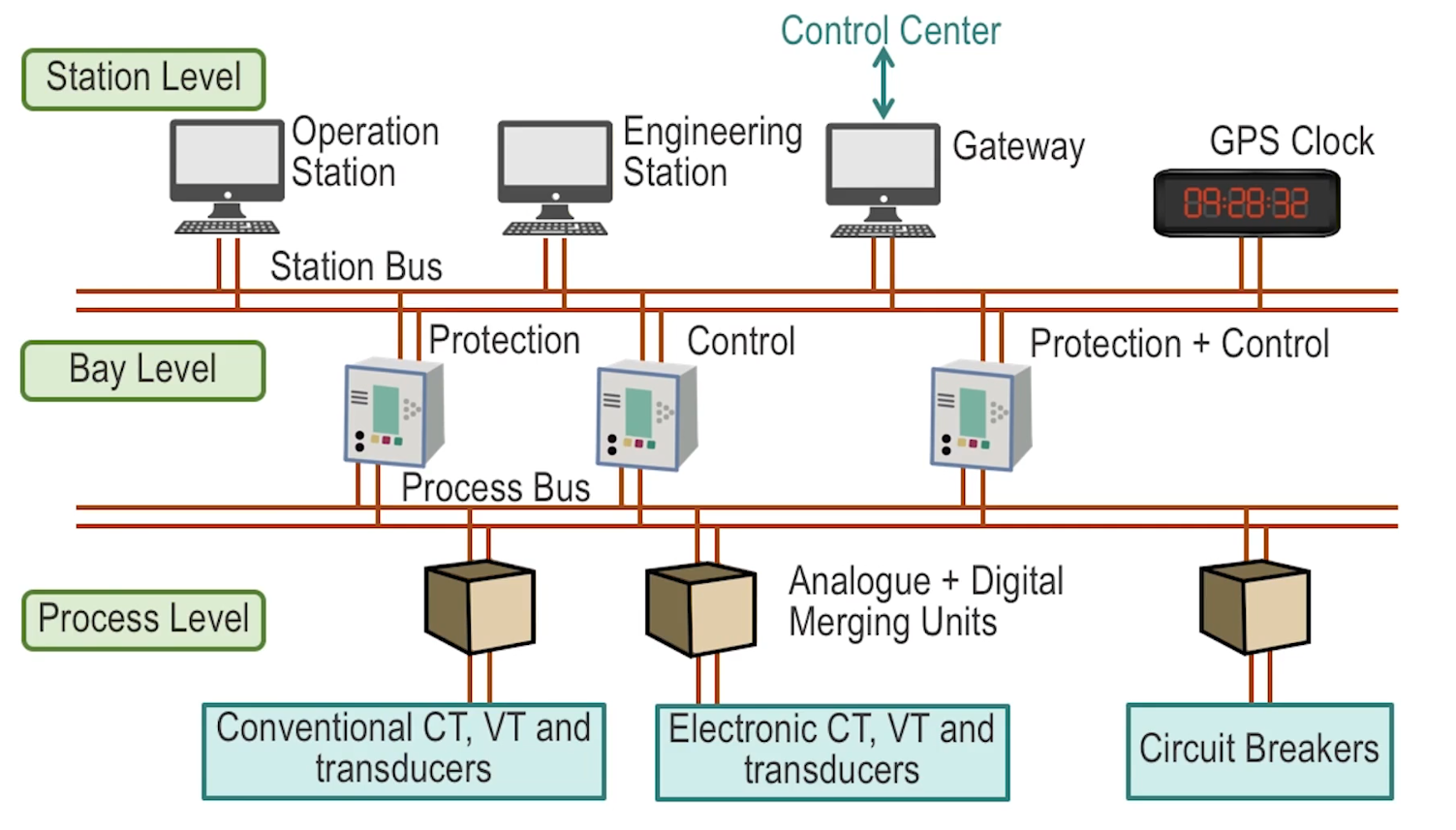

- International Electrotechnical Commission (IEC) standard 61850 was originally conceived for substation automation

- The design concepts are being incorporated throughout the generation, transmission, and distribution areas of the power industry and may even see adoption in the consumer/load component

- Extended to domains beyond isolated substation automation

- We will discuss in its original context, but these concepts are applicable wherever the standard is

- For almost 20 years, comms were done using coper wires and legacy protocols described above.

- This generally sucked, for a variety of reasons

- Ethernet has helped with some of this, but a broader solution was needed.

- Enter 61850

- First version of 61850 was released in 2005 with several broad goals

- Single complete standard for the equipment and related data in a substation:

- configuring

- monitoring

- reporting

- storing

- communicating

- Single complete standard for the equipment and related data in a substation:

- Aimed to permit interoperability of equipment afrom different manufacturers.

- Further, common format for this equipment’s data and configs

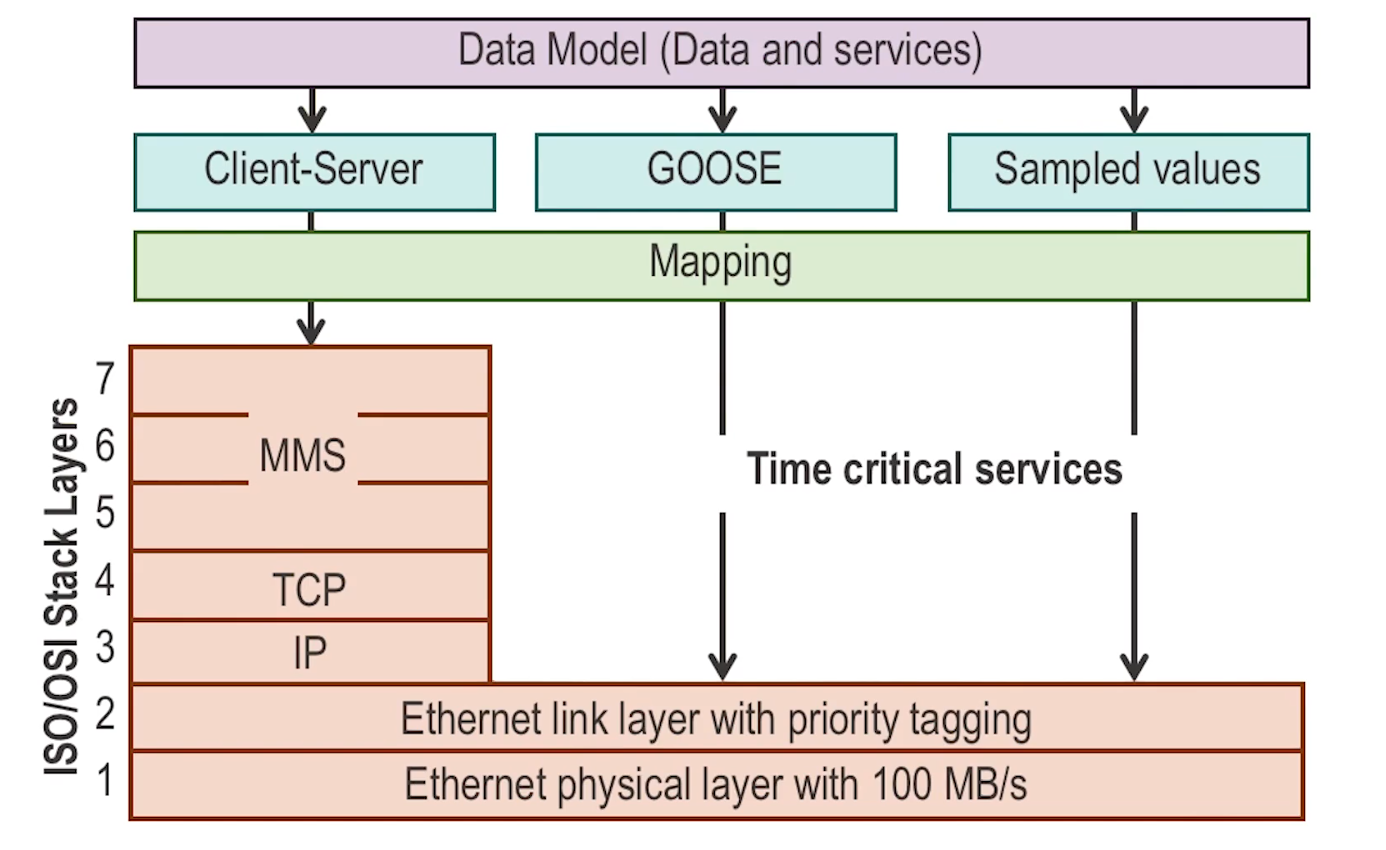

- Has a data and communications model

- Designed to run on top of a standard Ethernet LAN

- Can be either coper or fiber, but fiber is preferred for multiple reasons

- Defines two communication buses

- Process bus

- sends power systems information from CV/VT/Transducers to HMIs or PLCs or IEDs

- very sensitive to delay, so very high throughput

- Often has redundant components to ensure high availability

- Station bus

- connects all the IEDs to each other and to a router for external communication

- used for less sensitive data compared to process bus, but still built for HA

- Process bus

- Communications protocols can be classified into 3 different groups

- machine to machine

- based on generic substation event (GSE)

- a peer to peer layer 2 protocol that multicasts events to multiple devics, typically IED to IEDs

- Further divided into:

- Generic Substation State Events (GSSE)

- Seldom used

- Only state events

- Generic Object Oriented Substation Events (GOOSE)

- Most common

- Any event. In practice, all events.

- Generic Substation State Events (GSSE)

- Further divided into:

- a peer to peer layer 2 protocol that multicasts events to multiple devics, typically IED to IEDs

- based on generic substation event (GSE)

- client server

- configuration protocols

- machine to machine

- The 61850 standard does not include security specifications of its own

- defers to IEC 62351-6

- IEC 62351 provides security specifications for substation communications and is broken down into several parts

- 62351-3 requries TLS for all TCP/IP based communications, as well as node and message authentication

- Encryption is not supported because it would be impossible to maintain GOOSE’s 4ms performance requirement, so VLANs are used for protection

- This is not really secure. VLAN ID spoofing would allow an attacker to hop between VLANs, bypassing these Layer 3 controls

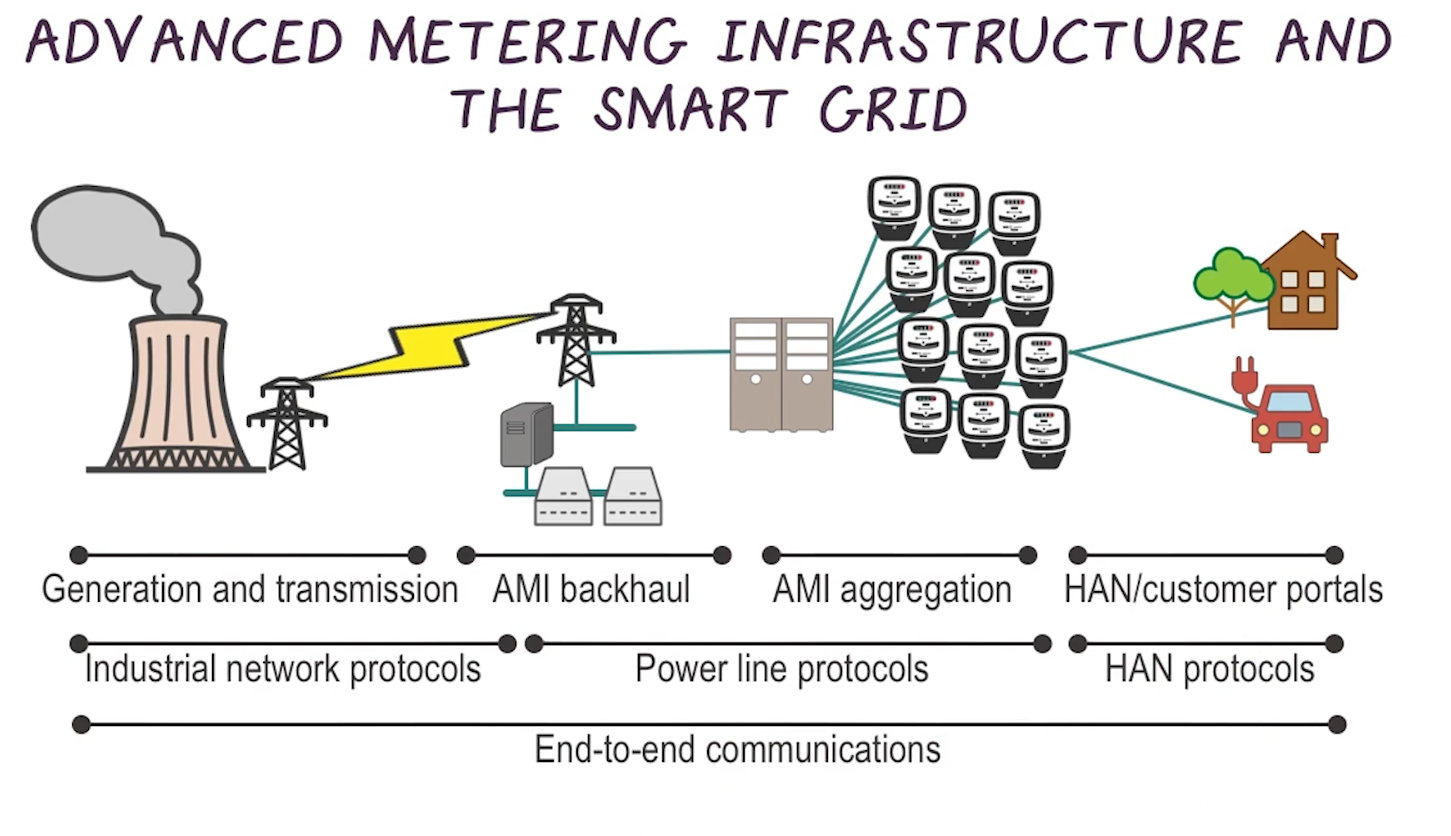

Advanced Metering Infrastructure and the Smart Grid

- The attack surface here is huge, and once compromised lots of traversal is possible

- AMI has lots of features that are very promising, remote everything basically

- Smart grid has introduced new protocols in the “Home Area Network” or HAN space

Security Concerns

- AMI

- it’s an extremely large network that touches many other networks. lots of attack surface

- The security concerns of the smart grid are numerous

- Smart grid protocols vary widely in their inherent security and vulnerabilities

- Smart meters are readily accessible, and therefore require board-level and chip-level protections

- Neighborhood, home, and business LANs can be used as ingress to the AMI and as a target from the AMI

- Smart grids are ultimately interconnected with critical power generation, transmission, and distribution systems

- Smart grids represent a very juicy target to a variety of threat actors

Security Recommendations

- Risk and threat analysis before smart grid deployments, in their planning stages

- similarly, assessment of the end users who will be connected to the grid, as they represent an attack vector

- Clear delineation, separation of services, and the establishment of strong defense-in-depth at the perimeters